_

Days

Hours

Minutes

Seconds

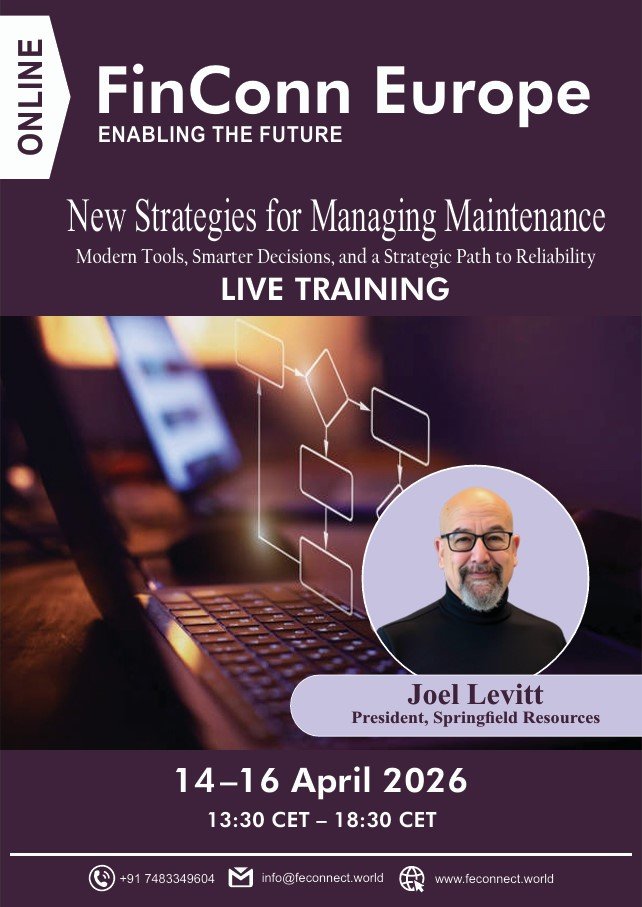

New Strategies for Managing Maintenance

Modern Tools, Smarter Decisions, and a Strategic Path to Reliability

LIVE TRAINING

14th - 16th April 2026

Meet the Course Leader

Joel Levitt

President, Springfield Resources

About Joel Levitt

CRL, CPMM, PROSCI CERTIFIED CHANGE MANAGEMENT PRACTITIONER

- President – Springfield Resources

- Past Director for International Projects, Life Cycle Engineering

- Past Director of Reliability Projects, Reliabilityweb.com

- Over 25 years of global maintenance management and reliability consulting experience.

Working with such global corporations as: Alcoa, Toronto Airport, Newfoundland Hydro, FedEx, Volvo, Iron Ore of Canada, US Steel, City of Edmonton, Syncrude, ARAMCO, Lockheed, SABIC, ADCO, BP, Exxon, BHP, Malawi Power, CISCO, General Motors, Mercedes Benz, Pepsi, NSA, Abbotts, US Coast Guard, US Army, US Navy…

- Author of 14 books and 200+ articles

- Trained 17,000 maintenance professionals in 550+ sessions in 39 countries

Course Overview

The world is changing. Maintenance management utilizes new tools, techniques, and approaches, yet it must still deliver machine capacity. This course combines new technologies with traditional, successful approaches to managing asset maintenance.

Our promise for this program is that you will gain a new and more in-depth understanding of reliability and maintenance, as well as a deeper understanding of how to manage a modern maintenance function. With this understanding, there will be a dramatically increased ability to design, plan for, and manage these activities.

Do you have retirements and are losing skills? Want to brush up your skills? Do you have newer people and want them to be productive? Do you want everyone to share a vocabulary? Want to promote cooperation with other groups (purchasing, stores, engineering)? These are the critical issues facing maintenance departments, worldwide.

Some of what you will learn

- Ways to cut the cost of your repairs by teaching 5 planning techniques to your tradespeople

- Where is Artificial Intelligence being used in maintenance?

- How, when, and why to apply IIoT sensors

- How to ensure uptime with Reliability Centered Maintenance and how to use work sheets

- How to use 3 TLC techniques to slash breakdown

- Specific techniques for Lean Maintenance for the 21st Century

- Drones for safe inspections

In-sourcing and TPM: what is it, how and when to do it, and who to do it with - How to use the CMMS to help manage operator centered maintenance activity

- Maintenance financial modeling

- Can you use virtual reality for training (YES)

- How to compute the optimum intervals for component replacements and other preventive/predictive maintenance efforts

Case Studies and Exercises

- 3 case studies in patterns in maintenance. These are organizations that have different problems and see how these problems impact their necessary approaches to maintenance.

- Exercise in determining your pattern by talking through the different elements of your current operation.

- Case study in RCM. Look at RCM from the point of view of how you would do a study and what you would do with the results. An actual simple study is generated.

- Exercise how and where to use TLC (Tighten, Lubricate, and Clean) to minimize breakdowns (75% of breakdowns are from defects in these areas)

- Case studies in Predictive Maintenance.

- Exercise: How to apply the state-of-the-art “Total Productive Maintenance (TPM)” strategies and techniques?

- Exercise in new MRO tools. Use of the Internet to source spares

- Exercise: How to analyze maintenance alternatives using economic modeling.

- Case study: How to add 50% to the size of your crew without hiring anyone using planning and scheduling techniques.

- Case studies: Lean Maintenance has saved companies millions. Here are some examples

- Exercise: Design a Lean project. Go through the Lean waste identification system developed by the instructor

- Exercise: What are the resources you should gather and maintain to ensure effective maintenance operations? Look at what is both possible and important for your operation.

Who should attend

Maintenance managers, supervisors, leads, CMMS managers, planners, engineers, and people who are in training for these positions. There is also an advantage to having representatives from operations and the stockroom for their perspective and input. Designed for all types of maintenance environments including factories, buildings, and fleets.

Registration Fee

€1498 + €35 Admin Fee

Registration

Registration Fee for Indian Audience

Rs 1,51,317 + Rs 3,523 Admin Fee

Registration